Scraped surface heat exchangers

For continuous processing of viscous and other challenging products, the Contherm® range of scraped-surface heat exchangers means more for your production. More thermal efficiency. More yield. More quality. And ultimately, more profitability. When it comes to your business, who doesn’t want more?

- More options: As the only range with both single and double-wall scraped-surface solutions, there’s a Contherm® for nearly any application.

- More quality: Contherm® scraped-surface heat exchangers are engineered to prevent fouling while preserving key flavour and nutritive components.

- More savings: With innovations for improved energy efficiency and minimal maintenance, Contherm® can ensure the lowest possible cost of ownership.

- More reliability: Every Contherm® is built with proven components, and backed by a global network with over 80 years’ experience in heat transfer.

Related products

Discover the complete Contherm® scraped surface portfolio

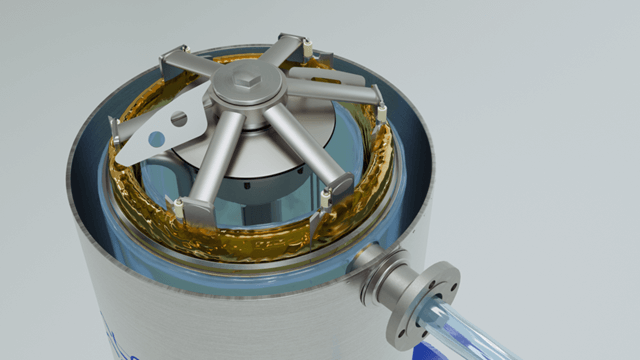

Contherm® scraped surface heat exchangers have long been trusted for processing viscous, sticky, and crystallizing products. Today, with the industry’s most complete scraped-surface lineup, Alfa Laval offers tailored solutions for nearly every production challenge.

As a global supplier, Alfa Laval is offering both single and double-wall scraped surface heat transfer systems. Contherm® at Alfa Laval stands out in versatility and innovation. Certain models are also engineered to handle extremely high product pressures.

Through close collaboration and process testing, Alfa Laval ensures that every unit is customized to meet specific customer requirements by providing optimized performance, durability, and product quality.

What is a scraped surface heat exchanger?

How is a scraped surface heat exchanger different from other static heat exchangers and how does it work? Learn more in this video.

Why choose Contherm®?

With 50 years of application experience, Alfa Laval is now the only supplier which offers the full range of scraped surface heat exchangers. Discover the advantages of working with Alfa Laval Contherm® in your production line.

Single wall or double wall scraped surface heat exchanger: Which Contherm should I choose?

Depending on your application needs, you may require a single wall or double wall solution, or a combination of different Contherm products. Here are the questions to ask, to help you make the right choice.

Even more with Contherm® Max double wall heat exchanger

Discover how you can increase your capacity with the new Contherm® Max and why this double-wall solution makes our family of products truly unique.

Proven to give you more

Cedar's Mediterranean Foods is a leading manufacturer of hummus, with products in stores across the United States. Thanks to Contherm®, they can ensure a quality, all-natural product capable of surviving a long shelf-life without preservatives.

More possibilities in more applications

The Contherm® range of scraped surface heat exchangers can provide high efficiency and capacity in duties with challenging process requirements that can result in loss of quality or fouling in traditional heat exchangers. This includes applications involving viscous, crystallizing, sticky or heat-sensitive products, as well as those with particulate matter.

As a result, Contherm® heat exchangers can offer endless opportunities for continuous and semi-continuous processing of products across many industries.

Personal care

Consumers have exacting demands when it comes to their choice of health and beauty products. Contherm® heat exchanger units can help your business reliably deliver quality in products such as:

- Body lotions

- Shampoos and conditioners

- Make-up products like mascara

- Toothpaste

Food

Contherm scraped-surface heat exchangers offer benefits in food applications where preserving valuable colour, flavour and nutritive components is essential. Example duties include:

- Soups

- Sauces

- Dressings

- Fruit and vegetable purees

- Jellies

- Yogurt fruit

- Hummus

- Cream cheese

- Spreads

- Confectionary

- Protein