A complete range of decanters for sludge dewatering and wastewater treatment

We offer a complete range of decanter centrifuges for wastewater treatment, sludge thickening and dewatering. Regardless of your demands or challenges, we have the right machine for you.

Dewatering centrifuges innovating the wastewater industry

When partnering with Alfa Laval, you have full access to our application experts who can advise you on how to optimize your operations. And with the backing of our extensive service network, you always get quick assistance whenever you need it.

Alfa Laval has been leading the wastewater decanter market for decades. With a strong focus on operational reliability, separation performance and high customer value, we continue to innovate centrifuges for wastewater treatment.

Aldec

Alfa Laval Aldec decanters bring high separation efficiency, reliable operation and low operating costs to all types of water and wastewater treatment plants. Aldec centrifuge for wastewater treatment is Alfa Laval’s medium range, comprised of a wide variety of sizes. Low power and polymer consumption in combination with easy service make Aldec very attractive in terms of total cost of ownership.

Available with capacities from 3 to 125 m³/h.

Benefits

- High separation performance

- Low power consumption

- Highly reliable operation

- Upgradable to G3

- Replaceable wear protection tiles

- PowerTubes

- Easy to service

Limitations

Aldec G3

The Alfa Laval Aldec G3 is a state-of-the-art decanter centrifuge for dewatering and thickening applications. It offers an ideal solution for duties where high separation performance and low power consumption are required. If your dewatering centrifuges demand maximum separation performance, the lowest possible power consumption, very high capacity and advanced control possibilities, a solution upgrade to the VecFlow™ design is possible.

Available with capacities from 23 to 225 m³/h.

Benefits

- Ideal for demanding sludges with high solids loading

- Equipped with Direct Drive gearbox

- Equipped with either PowerTubes or PowerPlates

- Upgradeable to VecFlow™ feed zone and SuperPond conveyor design

- High separation performance, 1-2% drier solids compared to standard decanters

- Low power consumption - up to 30% lower than standard decanters due to sludge centrifuge upgrades

- Replaceable wear protection tiles

- Advanced control system

- Easy to service

- Available in many materials, including Duplex

Limitations

- Larger footprint than i-Dec

Aldec G3 VecFlow™

Alfa Laval Aldec G3 VecFlow™ is a state-of-the-art decanter for dewatering and thickening applications. It offers an ideal solution for duties where maximum separation performance, lowest possible power consumption, very high capacity and advanced control possibilities are required. Aldec G3 VecFlow™ features the most advanced technology available on the market, including our unique VecFlow™ feed zone and Slimline conveyor.

Aldec G3 VecFlow™ is available with capacities from 23 to 230 m3/h.

Decanter for wastewater - benefits

- Highest performance at the lowest operating cost

- Extremely effective separation, 2% drier solids compared to standard decanters

- Lowest power consumption, 30% lower than standard decanters

- Lowest total cost of ownership

- Upgradeable

- PowerTubes, Slimline conveyor, Direct Drive gearbox and VecFlow™ feed zone

- Replaceable wear protection tiles

- Advanced control system

- Easy to service

- Available in many materials, including Duplex

Limitations

- Larger footprint than i-DW

Let us help you

Our customers:

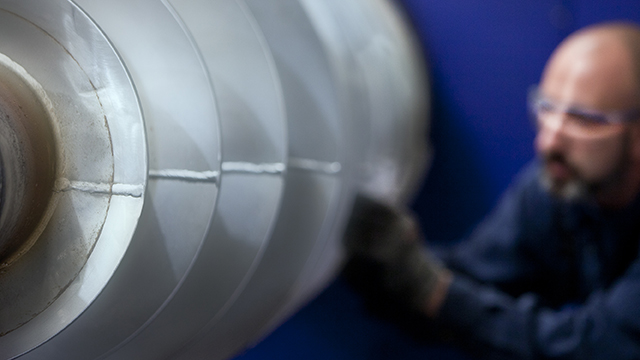

Extend your decanter’s lifetime value with Alfa Laval Service

Alfa Laval’s comprehensive service offering can assist you in your decanter centrifuge optimization as your operations develop and change over time. As part of the service offering you find both decanter centrifuge optimisation, troubleshooting and training, and more. Ensure outstanding performance from your Alfa Laval decanter and minimal total cost of ownership.

Alfa Laval ALDRUM G3 sets a new standard for sludge thickening

Difficult sludges that traditionally require liquid polymer to flocculate and thicken can be treated using a cheaper powder polymer – reducing your operating costs. Discover how the Alfa Laval ALDRUM G3 sets new standards for rotary drum filters

Support for Engineering & Construction Contractors

If your business provides engineering, procurement and construction (EPC) services, you know there are never enough hours in the day. There’s always another critical decision demanding your time and attention. So, when selecting decanters or rotary drum filters for a project, let us support you.