Power-to-X

Power-to-X (P2X) refers to the conversion of renewable electricity into clean fuels. It is a key component in decarbonizing the chemical, marine and aviation industries, and enables hydrogen to be transported across long distances.

Alfa Laval offers technology that supports each stage of Power-to-X. Over decades of supplying advanced solutions to the process industry, we have developed a diverse portfolio of heat exchangers to secure cost-effective production of clean hydrogen and fuels.

Alfa Laval’s solutions for clean ammonia

Ammonia is well-established as a cornerstone of the fertilizer industry, but it also plays an important role in refrigeration systems. Today, clean ammonia is used as e-fuel, as a hydrogen carrier, and more.

We continue our long track record as a partner to the ammonia industry with technology to support the demands of clean ammonia. In our extensive heat transfer portfolio, you will find the optimal solution for your plant with minimal production cost.

Contact us to learn more about critical heat exchangers, like process gas boilers, steam drums and ammonia condensers. We can also cover all your utility cooling and heating needs as you strive for maximum energy efficiency.

Alfa Laval’s solutions for e-methanol production

Combining renewable hydrogen with a CO2 source opens the path to e-methanol. Apart from being used as primary fuel for the marine industry or as storage medium, e-methanol is also instrumental for decarbonizing parts of the chemical industry.

With experience in large-scale plants and manufacturing, Alfa Laval supports this market, from small to giga-scale, with the same high quality of solutions and services.

We also offer a unique portfolio of efficient heat exchangers to enable carbon capture utilization and storage (CCUS) in the production of e-methanol.

We also offer a unique portfolio of efficient heat exchangers to enable carbon capture utilization and storage (CCU/S) in the production of e-methanol.

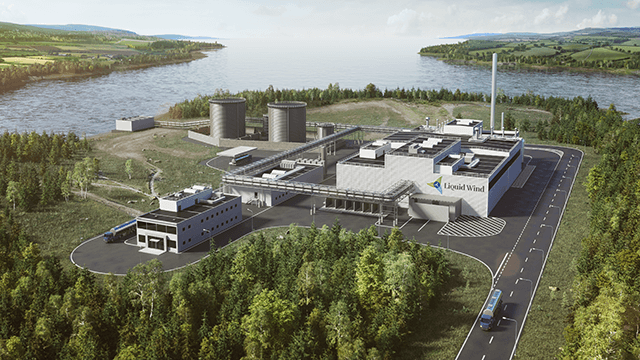

A partnership for renewable clean fuel production

Alfa Laval is an investor and partner to Liquid Wind, a unique Power-to-Fuel company that is developing commercial-scale eMethanol facilities. Each facility captures and concentrates biogenic carbon dioxide emissions from industry, combining them with hydrogen made from renewable electricity and water. The result is the production of green methanol. In addition to Alfa Laval, the Liquid Wind consortium includes Carbon Clean, Siemens Energy and Haldor Topsoe, among others. Our heat transfer expertise contributes to improving the process efficiency and the overall energy integration of the facilities. Heat exchangers are installed as key components in the main system, as well as in the process steps of green hydrogen, carbon capture and methanol synthetization.

Green ammonia as a fuel in the marine industry

In August 2020, Alfa Laval, Hafnia, Haldor Topsoe, Vestas, and Siemens Gamesa issued the report “Ammonfuel – an industrial view of ammonia as a marine fuel” based on our own industrial expertise and input from a list of competent industrial players.

Our solutions

Alfa Laval gasketed plate-and-frame heat exchangers

With our broad range of gasketed plate-and-frame heat exchangers, it’s easy to find your optimal solution – no matter the capacity of your plant. A compact design combined with outstanding heat transfer performance makes them ideal for skid building or tight installations, where you can’t afford to compromise on serviceability or energy efficiency. Product coolers, utility heating and cooling are some of the positions in which a gasketed plate-and-frame heat exchanger is a great fit for your power-to-X project. For critical positions like ammonia condensers, our semi-welded models give you even more options.

Alfa Laval Compabloc

Compabloc heat exchangers combine the temperature and pressure durability of shell-and-tube designs with the exceptional thermal performance of a traditional plate heat exchanger. The compact design is simple to install and up to five times more efficient than a comparable shell-and-tube heat exchanger. Compabloc can handle the most demanding one-phase as well two-phase duties like the methanol distillation section, making it a versatile problem solver for your power-to-X process.

Alfa Laval OLMI

An OLMI heat exchangers fits in for any requested heat recovery duties in processes with high temperatures and/ or high pressures, making them especially suitable for in ammonia and methanol production. Its outstanding reliability, superior fabrication and low CAPEX allow you to enhance energy efficiency, increase profitability and improve sustainability. The OLMI design, combined with superior welding technology, enables greater reliability than peers’ comparable solutions, resulting in extended lifetime, peace of mind operation and a lower environmental impact.

Alfa Laval Packinox

Packinox heat exchangers are ideal for combined feed-effluent heat recovery duties in large ammonia and methanol processes. Outstanding thermal performance, superior hydraulic efficiency and a compact design allows you to optimize energy efficiency and maximize process capacity with the lowest environmental footprint. A Packinox recovers more heat with lower cycle pressure drop than traditional solutions, resulting in a reduced investment for feed furnace and recycle gas compressor capacity, thereby ensuring faster ROI.

Alfa Laval Niagara Wet Surface Air Coolers (WSAC)

Alfa Laval Niagara Wet Surface Air Coolers (WSAC®) are custom-built, closed-loop cooling and condensing systems that combine high performance, low operating costs and reliable operation. They provide maximum cooling in a compact unit with minimal water and electric power consumption. The robust and simple design also provides stable thermal performance and low maintenance requirements. Our WSAC systems can be fully customized to your requirements, including designs for withstanding corrosive media, cooling multiple process streams in parallel, running both dry-cooling and wet-cooling mode.

Heat transfer solutions for carbon capture, utilization and storage

You may have heard of carbon capture, utilization and storage (CCU/S), but did you realize the technologies to enable it have been around for decades? With limited options for decarbonization in sectors like oil & gas, power, refinery, petrochemicals and cement industry, CCU/S will be fundamental for the future of the energy market. Discover our portfolio of heat transfer equipment designed to maximize the efficiency of carbon capture.

Heat transfer solutions for methanol production

Reliability, energy efficiency and product quality are of utmost importance to any methanol plant. Alfa Laval has vast experience in supplying expertise as well as proven equipment and services to methanol plants owners. Whatever your needs, we’re here to make operations trouble-free and bring you peace of mind.

Heat transfer solutions for ammonia production

To remain profitable, ammonia producers worldwide must continuously improve overall energy efficiency. With vast process knowhow and a broad range of equipment and services, Alfa Laval can help optimize energy-intensive ammonia processes with our compact and highly efficient heat exchangers.

Energy efficiency

Clean energy

Sustainable partnership

Contact us to learn more

Contact us today for more information about our sustainable solutions