Zero Liquid Discharge

Turn waste into value with an Alfa Laval ZLD system. These robust, compact solutions treat wastewater from industrial processes and recover valuable products during recycling operations. Materials are efficiently removed from the water, or wet material, and reduced to solid waste that can be sold, reused, or more efficiently disposed of. ZLD systems benefit both the environment and your bottom-line and are easily adjusted to meet your expanding needs and changing regulations.

Smart solution to remove liquid waste and recover valuables

- Increases water usage efficiency by removing liquid waste and treating water for reuse

- Some processes may recover valuable resources such as metals and minerals

- Easily adjustable systems are future-proof to your growing needs and changing regulations

- Less waste means lower disposal costs and reduced need for new resources

- Lower investment, installation and operational costs compared to traditional evaporation technologies

Effectively dealing with industrial wastewater is often a legal obligation, and necessary to retain your license to operate. But an Alfa Laval ZLD system can be a part of the process of recovering valuable resources from the waste that would have been lost. Alfa Laval’s product offering and technology expertise can play a key part in your resource recovery process.

Wastewater treatment

Alfa Laval Zero Liquid Discharge systems remove water from the waste so that valuable solids can be recovered from the resulting concentrated stream. The removed water can also be reused, increasing water usage efficiency.

Product recovery and recycling

Recover valuable resources that can be reused or sold when you add an Alfa Laval Zero Liquid Discharge system to your resource extraction and recapture process.

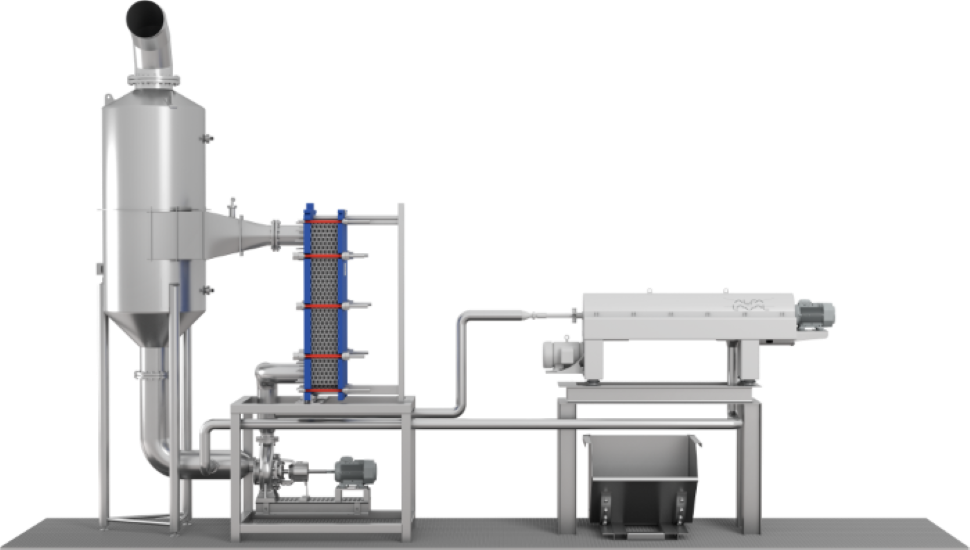

Get an overview of the Zero Liquid Discharge System

Learn more how Alfa Laval solutions can turn waste into value-add product by exploring the Zero Liquid Discharge system.

A choice of configurations

Mechanical vapor recompression (MVR)

Alfa Laval ZLD systems can be designed with MVR using electrical power to drive the evaporation process. An electrically driven fan increases the condensation temperature of the vapor in the evaporator before it is routed back to the heat exchanger where the latent heat is recovered. This configuration is ideal when there is no thermal heat source and when boiling point elevations are moderate.

Multi-effect systems

Alfa Laval ZLD systems can be designed using a thermal heat source such as steam or hot water, with one or several effects depending on the capacity requirements and your energy efficiency targets. The configuration is ideal when thermal heat sources are available and is generally more attractive in terms of capital expenditure.

AlfaFlash working principle

Dig deeper into the functions of the Alfa Laval Zero Liquid Discharge system. Watch the AlfaFlash animation and experience our forced circulation evaporation technology first hand.

Alfa Laval opens state-of-the-art service centre that recycles almost 100 percent of its water

Alfa Laval's new service centre in Frechen, Germany, will be one of the largest for plate heat exchangers in the world. In addition, it is also a technically advanced and sustainable facility, capable of recycling almost 100 percent of its water using Alfa Laval Zero Liquid Discharge technology.

Zero Liquid Discharge test unit

There are many benefits to installing an Alfa Laval Zero Liquid Discharge system, but you don’t just have to read about them. Experience the benefits for yourself by booking time with our test unit, and you can see how ZLD can positively impact your business.

Customer cases

Distillery achieves zero liquid discharge with Alfa Laval water recycling system.

Case story: Read more about how Alfa Laval designed a customer specific solution to treat waste water from distillery operations in order to save money on water, energy and treatment.

“Once we discovered Alfa Laval’s AlfaVap technology, we’ve never looked back."

Read more about how the Alfa Laval solution helped Fountain Quail recycle up to 80 percent of “flowback” wastewater for future use – protecting a valuable natural resource while maximizing gas production.

Turn waste into value!

Alfa Laval industrial water and waste treatment solutions helps to reduce your environmental footprint from water and waste streams. With our robust technologies you maximize reuse of water and minimize energy consumption by turning waste to value – time and time again!