Grape juice extraction FAQ

Juice extraction is an essential process in winemaking. The traditional ways to do this are with different kinds of presses and then filters or settling tanks, in which gravity makes particles, sediment and solids gradually fall to the bottom. Innovation in centrifugal separation technology offers a more efficient yet gentle way of extraction.

What are the advantages of centrifugation?

Replacing traditional technology with modern centrifugal separation makes it possible to drastically simplify and speed up some of the key processes in modern winemaking, and free up valuable floor space that you can use for other equipment to expand your winery’s output and capabilities.

Centrifugal separation makes it easy to process the incoming grapes and limits the number of steps needed to prepare the juice for fermentation or evaporation.

As the results are high-dryness solids and a clear juice almost free of solids, wineries benefit from big reductions in lees volume and tank bottom residues.

You can eliminate draining, pressing cycles and clarification, paving the way to a more efficient, continuous production flow – and saving on labour costs as well as doing away with space-hogging holding tanks.

If you use mechanical harvesting, the de-stemming step can also be eliminated.

How does it work?

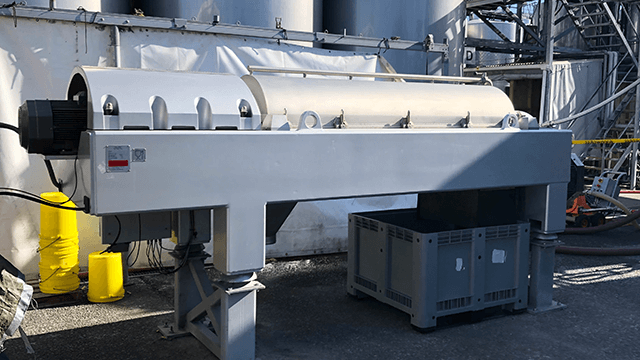

Grapes enter the reception area and the stems are removed. A centrifugal separator – called the Foodec decanter - then separates the juice from the skin and seeds, in only a few seconds. Compared to traditional batch-operation pressing systems, this advanced-technology separation process ensures you a clarified must of consistently high quality and in a continuous flow.

The Alfa Laval Foodec unit separates solids from the liquid in one single continuous process, using centrifugal forces thousands of times more powerful than gravity. When the denser solid particles (which in winemaking are mainly grape skins and seeds) are exposed to such forces, they get pressed outwards against the rotating bowl wall, while the less dense liquid (the grape juice) forms a concentric inner layer.

The sediment formed by the solid particles is continuously removed by the screw conveyor, which rotates at a different speed than the bowl. The dry solids then automatically discharge from the bowl.

What varieties of grapes can be used?

Centrifugal separation is ideal for white, rosé and red wines where fermentation is carried out in the liquid phase, and widely used by major wine makers around the world.

In New Zealand, where decanter extraction is starting to gain traction, the technology is used for Sauvignon Blanc grapes by a growing number of contract wineries.

For processes used in making red wine – such as thermovinification – Flash Détente and enzymatic maceration are fundamental for ensuring better extraction of tannins and anthocyanin pigments from the skin to the juice before these are separated. Unlike when using traditional presses, Alfa Laval Foodec technology does not result in any loss of colour.

When colour extraction has to be kept at a minimum, as with rosé wine, there are big benefits to be gained from the rapid processing available from Foodec decanters. The colour is adjusted during the previous maceration time and you can control it easily due to the rapid extraction. This results in rosé wine of high quality. This contrasts with traditional presses, where the long cycle has big negative effects on colour extraction.

Does centrifugation damage the grapes?

With a Foodec solution, you can process the grape inputs gently, avoiding any grinding or abrasion that results in excessive phenols. This enables wineries to recover a high-quality juice that is fully comparable to free-run juice and first presses in terms of pH, conductivity, etc.

Are there other applications and uses for this technology?

Foodec-based solutions are increasingly becoming the separation equipment of choice in key wine industry processes that include extracting juice from fresh grape mash or after thermovinification.

The decanter can also be used to recovering more wine from lees, separate juice from sulphited lees and concentrate crystals cream.

Moreover, separation technology also presents a cheaper and easier way to deal with filter slurry from earth filters (with diatomite or kieselguhr). Treating water from effluent Foodec decanters can also be used to reduce the organic matter and solid residue in the effluent from your winery, so it can be disposed of to a wastewater treatment plant.

Customer reference: Giesen Group

For Giesen Group, sustainability and environmental considerations are vital as we grow and expand the business. The decanter helps to maximise yield from scant resources, especially a reduction in water use. A decanter requires substantially less water to clean than a press (at a ratio of 1:3) or an RDV (Rotary Drum Vacuum) filtration (lees filter) device.

Read the interview with Duncan Shouler, Chief Winemaker, Giesen Group

Contact Alfa Laval New Zealand

Accelerate your grape juice extraction

Juice extraction is an essential process in winemaking. The traditional ways to do this are with different kinds of presses and then filters or settling tanks, in which gravity makes particles, sediment and solids gradually fall to the bottom. Now, the Foodec centrifugal decanter offers a gentle yet effective way to extract grape juice faster. Download the application brochure for wineries.